Some people like rain, and some people even like winter. But no one likes hailstorms, especially car owners. The damage from hailstones could vary from a couple of dents to broken windshields.

It’s no wonder why a lot of car insurance companies have to deal with a lot of applications after such unpleasant weather. Each of the applications needs to be processed through car inspection which will conduct either manual or automated inspection.

But how exactly do they estimate the damage costs? How does the process of hail damage inspection look in the first place? In this article, we will cover both of these questions.

How Was It Before? Hail Damage Assessment with Your Eyes

- Assessment of hail impact on vehicles begins with an initial visual confirmation of damage. That means examining the body of your car with your eyes and noting all the damages. You need to check the hood, trunk, side panels, and bumpers for any dents or scratches.

- Next, check the glass’s integrity. Even the smallest crack could lead to shattered glass, which is why documenting every small detail is crucial.

- You should also check for the water inside the vehicle. In some rare cases, hailstorms could break through the roof of the car. Some car insurance companies also ask for photographs of the damage.

But you can’t possibly notice and note every dent and scratch right after the hailstorm has passed. That’s where the damage scanning system comes in.

What’s Changing? The Power of Innovative Auto Inspection Solutions

There are two methods of automated inspection: 2D scan and 3D scan.

- 2D scan comes down to taking pictures of a damaged car with different lights and then using computer vision to detect any dents, cracks, and scratches.

- 3D scan is more complex since it fully scans a vehicle, makes its 3D model, and compares it to a pre-hailstorm 3D model of a vehicle.

Both methods have pretty similar results and use the same technology concept, so it’s easier to cover them both at the same time.

The general logic is that the car goes through an arch with cameras and lights to take high-resolution pictures of the vehicle’s exterior.

Our guide on AI technologies used for vehicle damage detection

Read more

Pictures are then analyzed by an algorithm to assess the damage. This algorithm is specifically trained to distinguish between types of damage (dents, scratches, etc.) and their severity.

Usually, damage inspection systems are integrated with automotive repair databases. This allows communication between insurers and owners without unnecessary hurdles. Since it is connected to the repair database, it can also estimate repair costs.

The result of automatic scanning is the report that documents all of the hail damage, including high-quality pictures of damaged areas. This documentation is valuable for insurance claims and repair costs and much faster than manual inspection since it can be done in just a couple of minutes.

AI Hail Detection System: Practical Insights from the CHI Team

The Netherlands is a country with pretty dull weather. It rains almost every season with nasty hailstorms during winter. For car owners, hailstorms usually mean dents on their cars. For car repair companies, it means an influx of customers with cars that need to be inspected.

This process is very time-consuming, especially when it is done manually. That’s why our Dutch client was looking for a solution that could automatically detect hail damage and count dents on the vehicle.

The main goals of this solution were:

- An accurate detection and count of hail dents;

- An improved vehicle scanning system for handling hail damage;

- The automated process of detecting damage, acquiring real-time images, and identifying the scale of the damage.

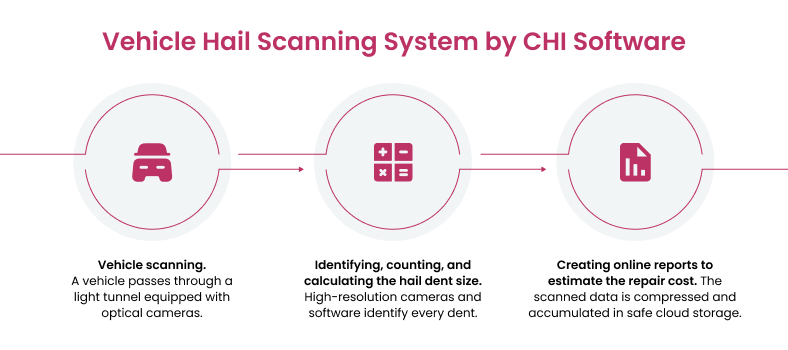

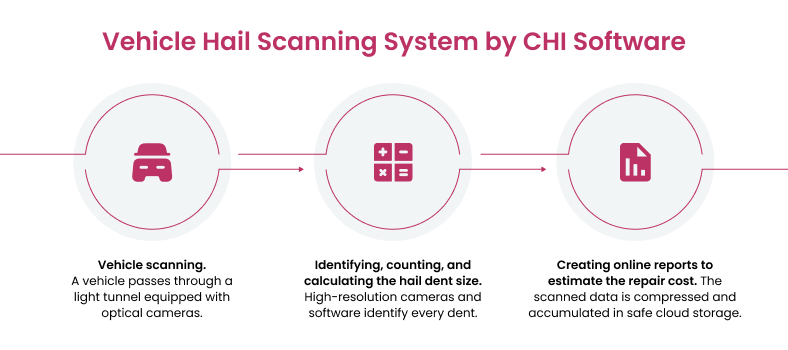

The solution we provided perfectly covered all of the client’s goals and was delivered in two weeks. The detecting process takes approximately one minute in total. Here’s how it works:

- A vehicle passes through a light tunnel equipped with optical cameras;

- High-resolution cameras and the software identify every dent and generate a report based on the damage level;

- The scanned data about the vehicle’s condition is compressed and accumulated in cloud storage.

Need a hint on how to optimize your business with advanced AI inspection? We have a few ideas!

Contact our team

This solution allowed our client to offer new services at the company’s stations, such as determining the exact level of damage and checking the surface of the vehicle. The data received in the process is a helpful tool for insurance cases. To learn more details about our solution and hear testimonials from our employees, click here.

Manual vs Automated Inspection: Transformations Are Coming

While manual inspections are still more common, that doesn’t mean that the change won’t come soon. New technology integration is usually sequential, and we can see that the first steps are already taken. Automated inspection tends to be a complementary method to manual inspections.

If we compare these two methods, we can see the strong sides of each.

Automated inception is

- Cost-efficient. Automating hail inspection is much cheaper compared to manual inspection since it doesn’t require a human worker to do any manual labor.

- More accurate. The computer vision system is more accurate compared to the human eye. It’s trained specifically to look at dents, scratches, and other surface defects caused by hailstorms.

- Relies on quality equipment. Damage inspection systems work best when paired with high-quality images. Image sharpness and the amount of noise may affect an algorithm’s ability to notice some damage.

Find more computer vision applications in our article

Click to read

On the other hand, manual inspection is

- More thorough. Some damage types can’t be detected by automated inspection, for example, deterioration.

- Time-consuming. While an automated system can inspect in minutes, it will take a human at least a couple of hours.

Conclusion

Automated hail inspection is a fairly new technology that is being slowly implemented in the vehicle inspection process. It is very time and cost-efficient and enhances customer experience.

Because of its ability to generate damage reports with pictures of damage, it is a valuable tool for any car owner or insurance company during hailstorms.

Automated hail inspection has clear advantages over manual, but such systems can be hard to create for some businesses. We at CHI Software already have experience with this type of system and much more – contact us today, and we will reach out to you shortly!

FAQs

-

What is AI-based hail scanning?

AI hail scanning is a technology that allows for automated hail damage inspection. It uses computer vision to detect dents and scratches and then generates reports about the overall damage to the vehicle.

-

What are the main advantages of using AI for hail damage inspection?

The main advantage is its cost and time efficiency. Compared to the manual inspection which could take up to an hour, automated inspection is done in minutes, saving a lot of time for the customers and employees.

-

Can AI hail scanning systems completely replace manual inspections?

AI hail scanning solutions have some limitations to them, so it’s best used as a complementary method of manual hail damage inspection.

-

What types of damage can AI-based systems detect that manual inspections might miss?

Most of the hail damage comes down to dents, scratches, and cracks. While manual inspection can cover the obvious ones, it has limitations due to human negligence. AI-based systems are specifically trained to detect all the damage, making them more efficient compared to humans in this regard.

-

Are there any limitations or challenges with AI-based scanning systems?

While it is true that computer vision in such systems is trained specifically to detect damage, it could give worse results if low-quality images are used. Great work requires great equipment, so for your automated damage inspection system, we recommend using high-quality pictures and cameras that could provide them.

About the author

Alex Shatalov

Data Scientist & ML Engineer

Alex is a Data Scientist & ML Engineer with an NLP specialization. He is passionate about AI-related technologies, fond of science, and participated in many international scientific conferences.